|

Weeds? Pain in the proverbial. We all know that herbicides will eventually lose efficacy due to herbicide resistance, and the rate of new modes of action are few and far between, combine that knowledge with Metabolic resistance and we could be stranded relatively quickly, but what is a realistic answer to this problem? “At the end of the day we have precious resources, water, sunlight, nutrients - they should go into growing food, fibre and energy. Going into weeds that don't need to exist in the first place is a waste, spending resources on getting rid of them is wasteful and spraying anything other than weeds is again, a waste. There is a lot of innovation still to be had in this space but there is so much out there already that can be adopted today” - Dr Nick Berry Throw everything at themWeeds are excellent at surviving, adapting and evolving to whatever we throw at them, which is why we need to mix up our weed control strategies. David Brunton from The University of Adelaide's Weed Science Research Group is researching strategies to prolong the effectiveness of these herbicides by incorporating diverse and sustainable crop production practices “we’ve spent the past 20-30 years using herbicides to control weeds, think of what you will do in 5-10 years if we continue to rely on herbicides and are no longer able to control problematic weeds using herbicides due to resistance?” he says. Annual ryegrass is one of these problematic weed species, which has developed resistance to a number of pre and post-emergent herbicides, across multiple herbicide groups (modes of action). The current story of herbicide rotation has clearly been demonstrated as a non-sustainable long-term tactic. Incorporating non-herbicidal methods of weed control in combination with strategic herbicide use is fundamentally the way forward. So what are some of the options?

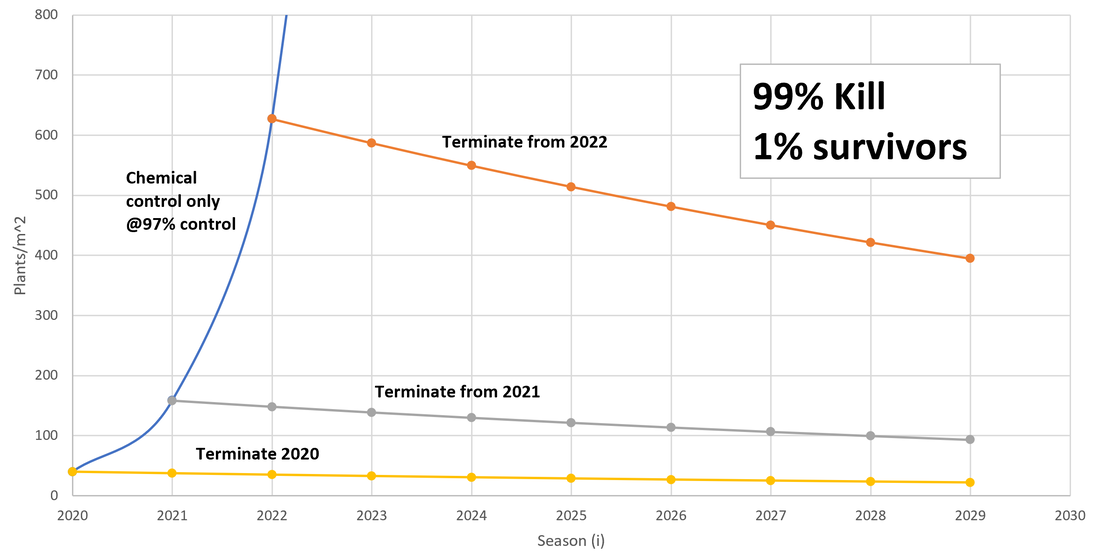

Why Harvest Weed Seed Control? “It seems crazy that we spend a lot of time and money killing weeds all year only to reward the survivors at harvest and spread them out so we have something to spray next year” - Peter Newman, Planfarm Extension Agronomist The weeds present at harvest are the fittest, they are the ones who have escaped in season control. We know that each surviving weed can produce a huge number of seeds to spread back onto the paddock to be the following years weed problem and worse yet, we wonder why the weeds missed the in-season control, was there a spray issue? Have the weeds evolved dormancy? Or worse, are the surviving weeds herbicide resistant? Dr Nick Berry states "you couldn't design a better weed seed spreader than a combine harvester. It separates the grain out, then the weeds go round and round the tailings, distributing them nicely across the paddock." There are three aims with HWSC 1 | Stop the spread of weeds 2 | Drive the weed population down 3 | Target Herbicide Resistant weeds You can see from the graphic below at harvest we have a real opportunity to target the fittest weed seeds with Harvest weed seed control measures. Using the Seed Terminator weed and volunteer seeds are captured and pulverised, preventing them from being spread back onto the paddock to grow next year. By adding weed control at harvest farmers are able to specifically target any potential herbicide resistant weeds while reducing the weed seedbank each season without any additional passes and controlling the green bridge. This can result in maintaining the longevity of herbicides in general but also allow farmers to be more selective with choices around herbicides and allowing them to lower production costs.

0 Comments

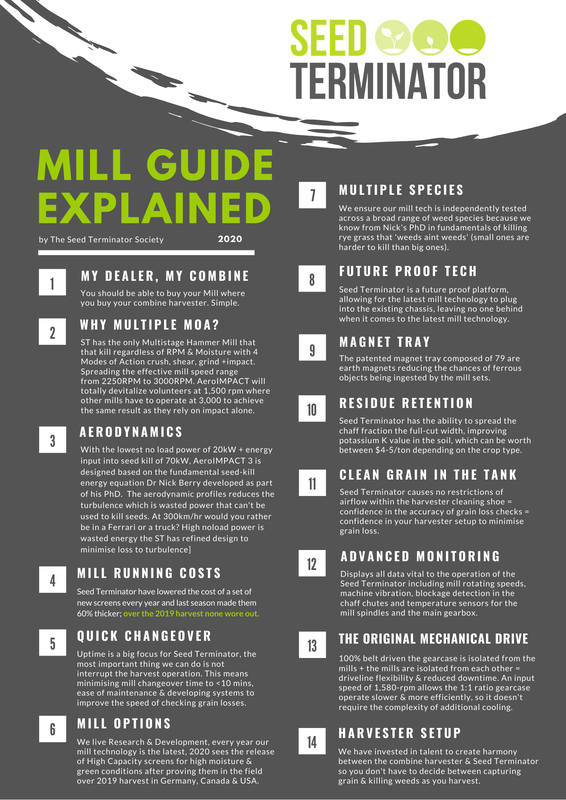

Dr Nick, the inventor behind the Seed Terminator shares how he came to design a mill to kill weed seeds onboard a combine harvester.

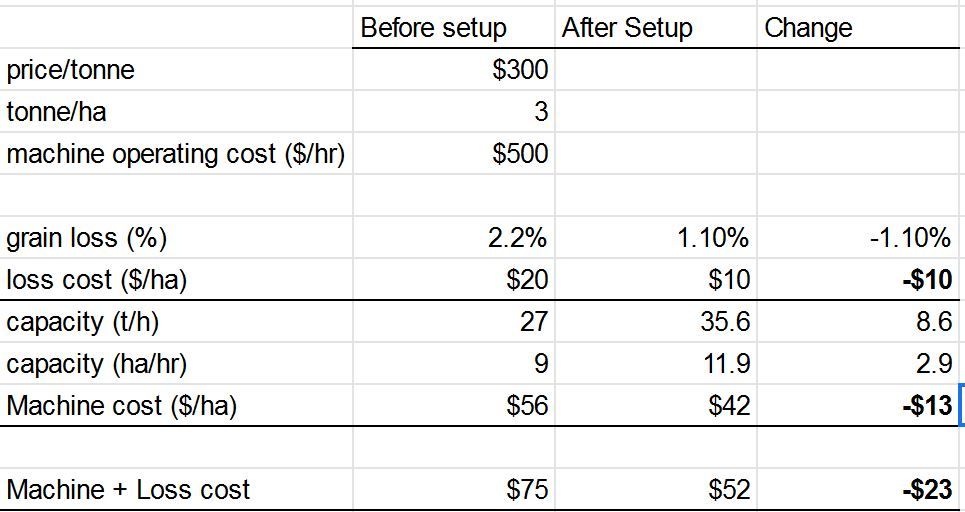

#ThanksDad What do you get when you bring together Kondinin Group engineer, Ben White with Seed Terminator harvesting expert, Brett Asphar, his wife Robyn and the Wongan Hills team from Boekemans Machinery?Brett Asphar has saved a farmer $23/ha by improving combine harvester setup, independently tested by Ben White of the Kondinin Group. That's an amazing outcome which demonstrates the importance of setup for best farmer outcomes. We filmed the optimisation, sign up to get the full videoWhen it comes to helping farmers win the battle against weeds while reducing reliance on chemicals, you might say one South Australian company is crushing it. Kangaroo Island-based Seed Terminator produces a mechanical device of the same name which pulverises weed seeds at the harvesting stage, before they get the chance to grow up and run riot among crops. The brainchild of the company’s co-founder, farmer/inventor Dr Nick Berry, the Seed Terminator tackles a problem inherent to crop farming: the fact the harvesting process is the weed’s best friend. Because when the crop is cut, once the chaff and grain have been separated, the harvester flings the chaff back onto the ground. This includes the seeds of weeds that have escaped or resisted the various stages of herbicide spraying – in other words, the toughest customers of all. When these survivors are redistributed, the whole harvesting process has simply set farmers up for problems the following year. ‘Problems’ may be an understatement. In 2016 Australia’s Grain Research Development Council estimated that weeds cost Australian grain growers about $3.3 billion annually, and – because weeds deprive crops of sunlight, water and important nutrients - yield losses of 2.76 million tonnes. They also put the cost of herbicide resistance at $187 million a year, for herbicide treatment and other weed control practices. Nick’s invention is a smart and cost-effective solution. The Seed Terminator is an attachment that retro-fits to most combine harvester brands, and it uses multi-stage hammer mills to pulverize weed seeds along with the chaff so they can’t sprout. What's left is a fine sawdust-like mulch that actually puts nutrients into any soil that it’s spread upon. Installed on a typical harvester, the system can distribute that mulch up to 14 metres. It’s a one stop weed killer and mulcher as well as grain harvester.

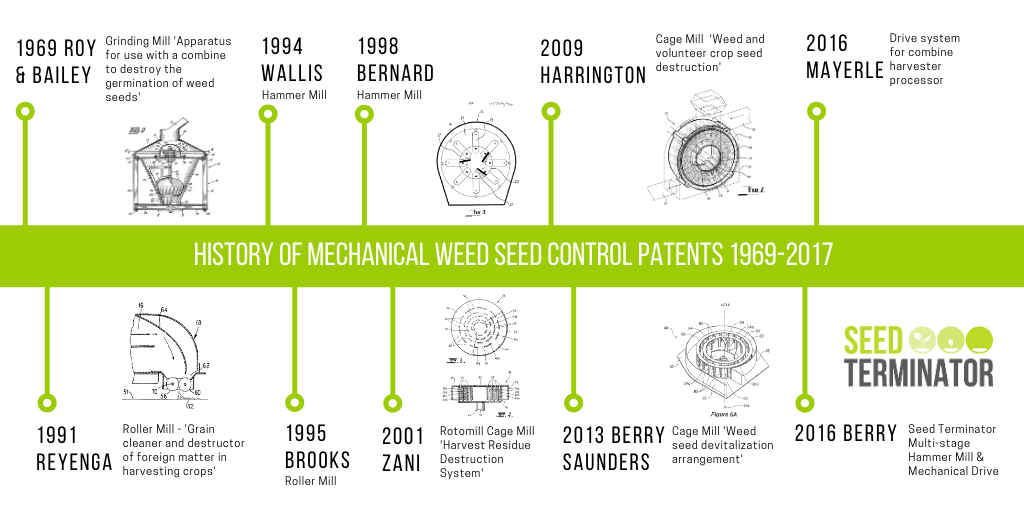

“What tillage does, by its motion, is it rips the ground open and dries out the soil. If you are in a moisture limiting scenario like most of Australia, then that reduces your yield,” says Nick. Then along came a significant change. “All of a sudden we started to get some really effective chemicals come out, like glyphosate, which facilitated a whole change in agricultural practice. We moved away from tillage altogether, particularly in Australia.” Still the world’s most used herbicide, glyphosate saw yields go up, and a lot of area that wasn’t suitable for cropping suddenly became viable. Then come the 90s things shifted again. “After 30 years, herbicides start to become an issue,” says Nick. Repeated use of the same herbicides led to herbicide resistance. A small minority of weeds of one particular species, thanks to a slight genetic variation, would be resistant to the herbicide. Over years of using the same herbicide, these survivor weeds would flourish and eventually dominate. The herbicides needed to be used more often and in stronger doses. So the focus shifted back to the machinery itself, with a wholesale change in harvester design. Phil Zani of Harvestair had the Rotomill Cage Mill working by 2001 but between 1995 and 2005 there was a doubling in capacity of machines and the design couldn't handle the throughput. There was a lot of investment in making these mobile factories more efficient, but the central problem remained; combine harvesters weren’t killing the weeds, merely redistributing them. Enter Nick. The farmer’s son and mechanical engineer had been paying close attention to developments in the field, and knew there must be a better solution. From 2010, the GRDC had stepped in, with money. They began to fund the work of farmer Ray Harrington, who had the idea of attaching to a trailer a heavy-duty mill originally designed to turn coal into briquettes but which could also crush weed seeds. But the Harrington prototype came with a few problems. First, weighing in at one tonne, the mill was a colossus. Second, it had to be trailed behind the harvester (class 9 or larger mind you). And then the biggie: the price tag. It was going to cost some $250,000 – out of reach for most farmers. “GRDC started to put money into it, and to realise that they needed some engineering.”says Nick The GRDC had engaged a consultant, Graeme Quick, to look at the prototype of the Harrington Seed Destructor (HSD). Quick concluded it would never be accepted by the American market unless it was integrated into the harvester. He proposed that a parallel project look into an ‘integrated weed seed terminator’ – (“The name Seed Terminator is my tribute to the great man,” says Nick). The project was to be run at the University of South Australia (UniSA) and, largely funded by grain growers’ levies through the GRDC, Nick was granted a scholarship for the work. His PhD research was to explore ways to kill weed seeds on board a harvester. This started with a prototype – which failed. Then it was back to the drawing board, looking at how much energy was needed to kill weed seeds. Then creating some computer modelling process to evaluate how to evaluate energy input into seeds in a mill.

“We’ve got farmers who are anywhere from 600ha to 20,000ha and they all run different brand harvesters and different size ones, but they all have sustainability issues with herbicides. They need an integrated approach, to be using herbicides but to protect them from resistance, and drive down the weed population with something mechanical. Our vision is to reach as many farmers as possible, as quickly as possible and as economically as possible. Affordability is really important. While we develop the tech, we also need to reinvest in making it better.

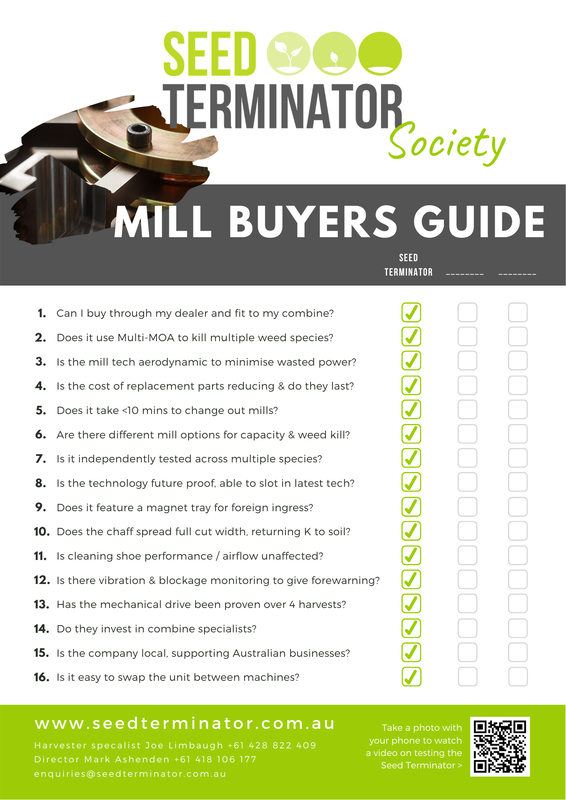

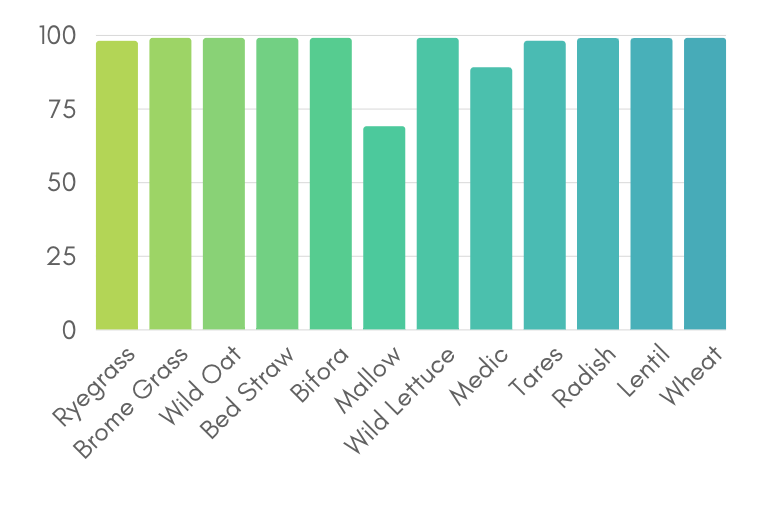

And so Nick set about developing his own machine. The first pilot Seed Terminators were introduced in 2016, and now there are some 250 machines in operation worldwide, each retailing for around $110,000. The design is constantly being refined but essentially it’s a mechanical system that uses the harvester’s drive to transfer power to two multi stage hammer mills. These grind, shear and pulverise the chaff once it has been been separated out from the grain – ensuring even the toughest weed seeds won’t be back. “With chemicals you have ‘pre-emergent’ herbicides, that you put down at the time of sowing,” explains Kelly Ingram, marketing director of Seed Terminator. “Then you have in-season herbicide spraying while the crop is growing. We come in at the end. We tidy up all the weeds that have been missed. Potentially they are herbicide resistant, or perhaps they grown later and managed to dodge the herbicides.” After working closely with farmer research partners over some 296 harvests, the Seed Terminator technology is paddock proven and farmer focused, says Nick. While they’ve increased the number of weed seeds killed by the mill, that’s not the only measure of achievement. They’ve also evolved the mill technology over the past four years to drive down the cost of the wearing parts and how long they last, and to increasingly decrease the amount of power used in the process. Seed Terminator also conducts ongoing trials in a number of universities in both Australia and overseas to test the ability to kill weeds. The University of Adelaide testing found the device able to kill 99% of notoriously tough rye grass seeds. “Seeds come in different shapes and sizes so you need to apply different amounts of energy to kill them. How we set the mill up in different parts of the world varies slightly. We also do field trials on how many seeds we can capture with the harvester.” Explains Kelly: “We have designed our technology so it can be pretty much used anywhere. The standard technology will go out to 98% of our farmers and will work fine and the other is the high capacity for when you have tricky conditions. The standard one works well in most situations." While the Seed Terminator is getting uptake in Europe, Canada and the USA, it’s all still a learning curve, says Nick. “We’re just trying to understand how it fits into other people’s farming systems. One of the biggest learning things is mindset differences and attitudes. Farmers in Australia are very innovative and happy to modify their machines and do something a little different in order to give them a long-term benefit. We hear words repeated like ‘I want to be able to leave my farm in a better state than I found it’. It’s a generational thing – they want to hand down the farm to their kids and grandkids.” He believes the public perception of farmers is often skewed, but Australian farmers’ ready adoption of technology that protects the land is tangible proof of how invested they are in longevity. “To go and spend $100,000 on a Seed Terminator is amazing.” “Farmers care deeply about their land and its ability to produce food for the world. That long-term attitude isn’t only in Australia but it is pretty unique. People come here and are gobsmacked that a farmer would spend more money on something that’s not necessarily going to deliver him a return this year but over the next four years.” Farmers are out there, day in day out, closely observing the life cycle of the plants and the soil. “They see the issue. They see it doesn’t make any sense to spread weeds with their harvester,” says Nick. “With Seed Terminator, they are getting revenge on their weeds." Quick to adopt new technology, farmers recognise innovation as their friend, says Kelly. “Farmers always have their finger on the pulse about the latest developments. People are coming to us; it’s farmers talking to other farmers, it’s word of mouth,” she smiles. “People are really excited about it. And it’s nice that it’s ag tech – it’s not an app. It’s a mechanical solution.” Meanwhile, Nick sees it as Seed Terminator’s mission to stimulate change, through commitment to R&D and developing further mechanical solutions to help farmers protect their crops. “We’re not only looking at how we can smash seeds but the whole system - how can we mechanically intervene to make farming more sustainable. We want to look at this as a holistic thing.” And from here, who knows where this journey of innovation will lead, but thank you to all grain growers who played a part thus far. MY18 Multi-stage Hammer Mill

Mechanical Drive - 31% Less PowerWe designed a mill that can handle drops in engine RPM without significantly effecting capacity or kill, which enabled us to harness the efficiency and simplicity of the mechanical drive without being tethered by fluctuations in engine rpm. Our drive is driven off the harvester’s engine with minimal moving parts, incorporating only shafts, belts and gearboxes. This is to maintain a lower power draw and fit to class 7-10 harvesters. We use precision machined custom bearing spindles and a custom, German made spiral bevel gearbox. The War on WearWe have attacked wear on multiple angles this year with

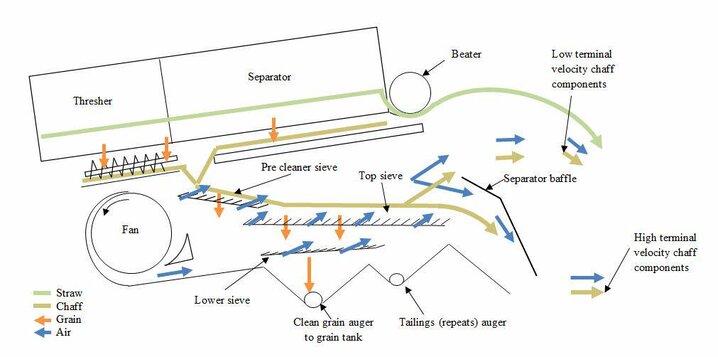

Aero-IMPACT 2.0We created the Aero-IMPACT 2.0 system that efficiently creates high air flow for maximum capture of weed seeds, minimum disruption of the harvester sieve and minimise infeed blockages. Uniquely able to maintain high air flow under highly loaded conditions even at reduced rpm. We have optimised the residence time that material is in the mill, to improve capacity, reduce wear and reduce over processing. We have also improved the aerodynamics of our impact elements which has meant less turbulence and therefore less wasted energy. The diagram above shows the movement of straw, chaff, grain and air in the harvester. The baffle-beater gap let's air escape unrestricted, too much air escaping above baffle = risk losing seeds. Seed Terminator's huge air flow means less air escaping above baffle = no cleaning shoe air restriction and maximum capture of weed seeds.

As you can see in the video material is sucked into Multi-Stage Hammer Mill even with the side covers off. South Australian Grains Industry Trust funded research conducted by Trengove Consulting in 2017 found ryegrass weed seed kill was 93% at 2250 rpm and increased to 98% or greater at normal operating speeds (2500–3000 rpm). Results also showed than 99% control of several other species including wild radish, brome grass,wild oat, bifora, bedstraw and tares and increasing chaff flow rate (harvest rate) did not reduce control of these species

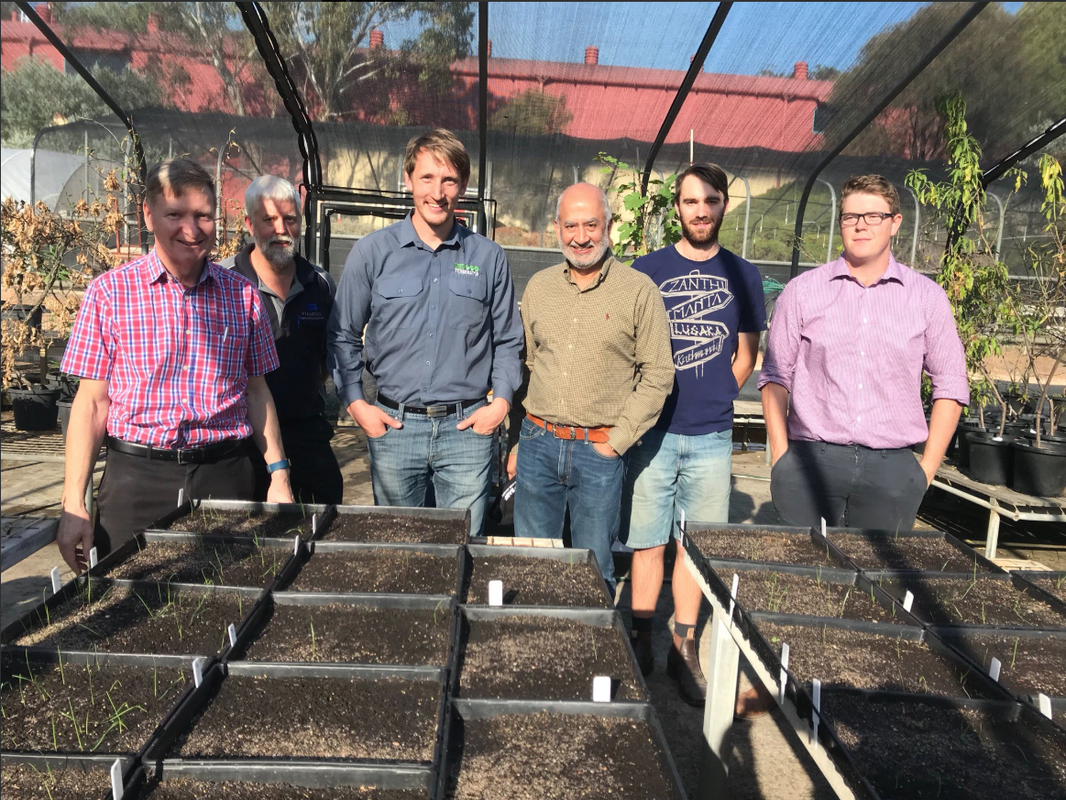

96% Kill Performance The Weed Science Research Group, a part of the University of Adelaide confirmed that Seed Terminator could consistently reduce germination of Annual Ryegrass by 96% compared to a control sample. Associate Professor Chris Preston, Geoff Philips, Dr Nick Berry, Associate Professor Gurjeet Gill, PhD Candidate David Brunton, Graduate engineer Keagan Grant

[ August 2018 ] After a few late nights fitting up the Seed Terminator, Nick spent two weeks operating the harvester, trying different Seed Terminator configurations, different harvesters setups, measuring grain loss, living and breathing harvest. There are a huge number of design changes for the MY2018 Seed Terminators. If it is one thing we have learnt, it is that what works in theory and what works in the field can be miles apart. There is nothing like proof in the paddock; being able to test the machine in Canada prior to our Aussie harvest is a great opportunity to get a jump start on 2018 lessons. Header (nee Combine) Uptime is a big focus for us, the most important thing we can do is not interrupt your harvest operation. We have already implemented a few tweaks to the design based on the early results in the field. We are gathering information on how to operate our new blockage sensors and a bushel of knowledge (excuse the pun) on how to drive the machine. One of the things we had to deal with in the early Canadian harvest was an abundance of green weeds at harvest, mostly Kochia; driving to conditions the Seed Terminator 'ate her greens' without a fuss. Others include high harvest moisture (15-18% Canola, 20% Wheat, 18% Peas), cold temperatures (haven't had a day above 20 degrees yet), moist conditions including harvesting during drizzling rain and working through tough canola straw, so far she hasn't missed a beat! AeroIMPACT 2.0 = Capacity, capacity, capacity

Early reports confirm the new AeroIMPACT 2.0 technology is able to replicate the increased capacity we saw in the lab, in the paddock; bring on Harvest 2018! |

Kelly IngramArchives

July 2023

Categories

All

|

Home

Seed TerminatorConversations with Farmers |

© COPYRIGHT 2020. ALL RIGHTS RESERVED.

|

RSS Feed

RSS Feed