0 Comments

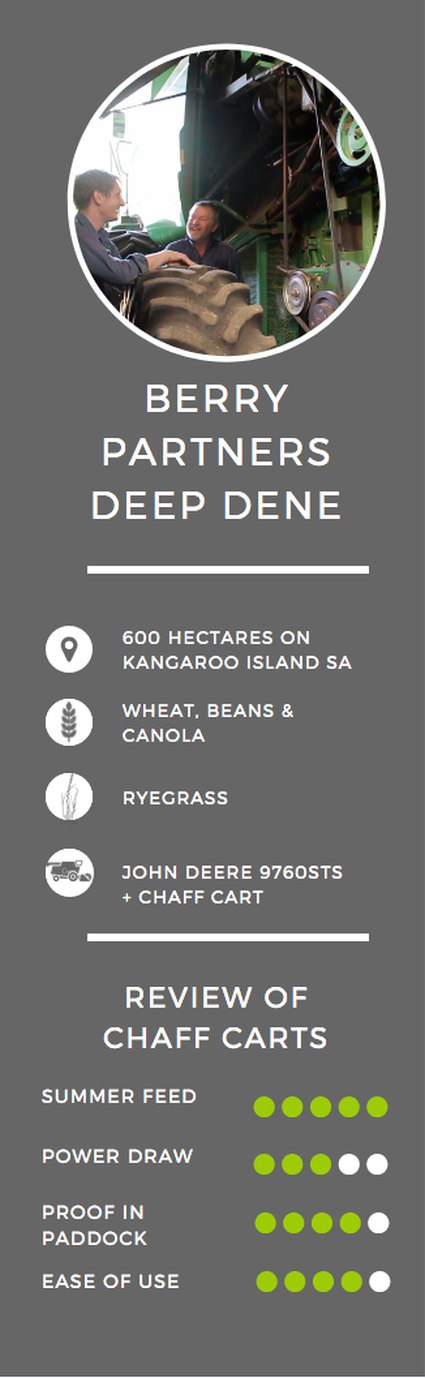

For our dual enterprise that extra month of feed is worthwhile, but we might do better crops with the residue retention. If we ran a Seed Terminator it would certainly be harder with the livestock side of things unless of course Kikuyu and all those other summer feeds kick in. If we were 100% crop we would certainly have a Seed Terminator, but with the integration and the synergies of our dual enterprises a chaff cart is a better fit. Has the chaff cart improved the weed burden in the three years you've been using it? I can see areas that have been bad, that are now ok, but if we have a non competition year from getting too wet and the crop fails, then the weeds tend to build up quickly. Its up to us to perhaps spray top them in that situation to die it down. but when your collecting the weeds, then killing the weed seed with the sheep and then having a competitive crop its been working really well. I don't think we'd be able to do continuous crop like we've done for 22 years without it. We've only burnt a some paddocks couple of years in that time. Returning residues to the ground is really good, avoiding burning and keeping our reliance off the chemicals. What crop rotations have you used in the past? How important is the combination of crop rotation, chemicals and HWSC? In the early days we rotated lupins, wheat and canola. Lupins were ok where they grew really well, but you'd have anywhere from 10% to 50% of the paddock not survive the winter, so all of a sudden every time you grew lupins you would more than quadruple your weeds, especially rye grass. After that we tried rotating just canola and wheat following the dollars, we wanted a legume but didn't know of any that would work well in our environment, other than pasture, but then a couple of growers on the Island brought in broad beans which worked really well. Broad beans built up our rotation and compete fairly well with the weeds. Having three reasonably competitive crops, in addition to the chemical regime, and the collection of seeds with the chaff cart, we feel we can keep going and not have to give up on farming. Nick Berry (left) with his mum and dad Lloyd & Christine Berry on the family farm.

How does it feel not burning and what did you do instead of burning this year? Burning an entire program of either windrows or chaff dumps was quite a time consuming job when you consider the time involved in the whole process from installing firebreaks around chaff dumps to lighting and monitoring fires and weather conditions. One of the things I enjoyed this year was not having to constantly monitor the wind forecast looking for good opportunities for burning dumps and then having to adjust the other farm activities to fit around this. This year we spent more time on doing some more liming, equipment prep for seeding. It certainly felt like we had more time. I think this is a difficult thing to put a value on but I believe that when I have seen it estimated at $2/ha it is undervalued…..obviously depending on what you choose to do with that time What do you think not burning does for your soils and future productivity?I think maintaining soil cover is important. Spreading the residue evenly across the width of the harvester is still a challenge though. We may see some N tie up from the build up of cereal stubbles in particular but I think the return of K into the system along with some moisture retention improvements should go a long way, if not beyond offsetting this.

|

Home

Seed TerminatorConversations with Farmers |

© COPYRIGHT 2020. ALL RIGHTS RESERVED.

|

RSS Feed

RSS Feed