Geek Out on Science

01

Stop the spread and manage the patches

02

Cut the costly sprays and save your crops

03

Delay herbicide resistance and keep costs down

04

Boost your yields by playing the numbers game

WE WROTE THE BOOK ON MECHANICAL WEED CONTROL

Putting Australia's highest performing mill to the test

South Australian Grain Industry Trust (SAGIT) Benchmark Report

2022/2024 Key Takeaways

Independently Observed by Kondinin Group

February 2024

SAGIT Mill Testing TL;DR

What insights can we learn from the SAGIT Benchmark Mill Testing?

Read more

SAGIT Mill Benchmark Testing 2022

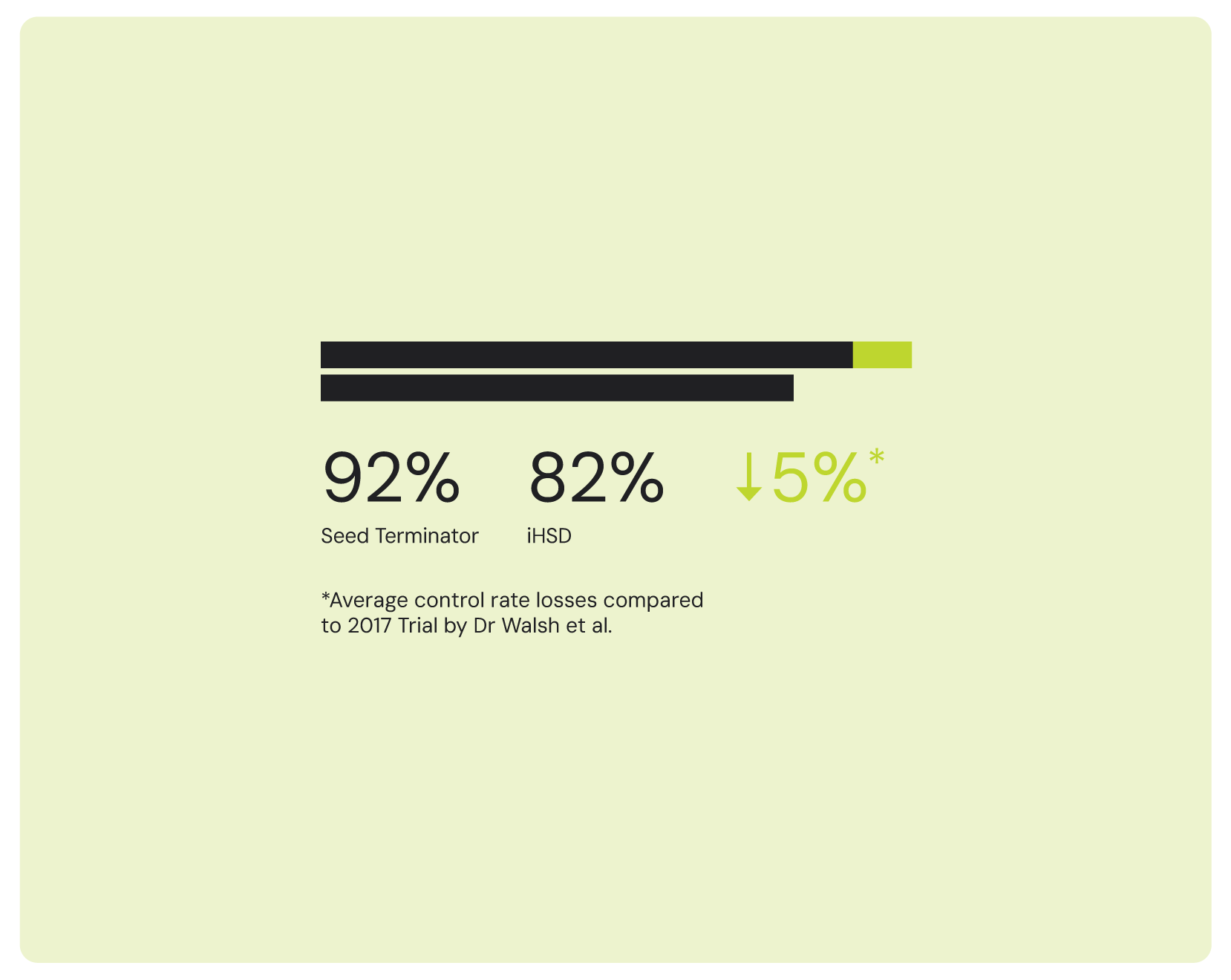

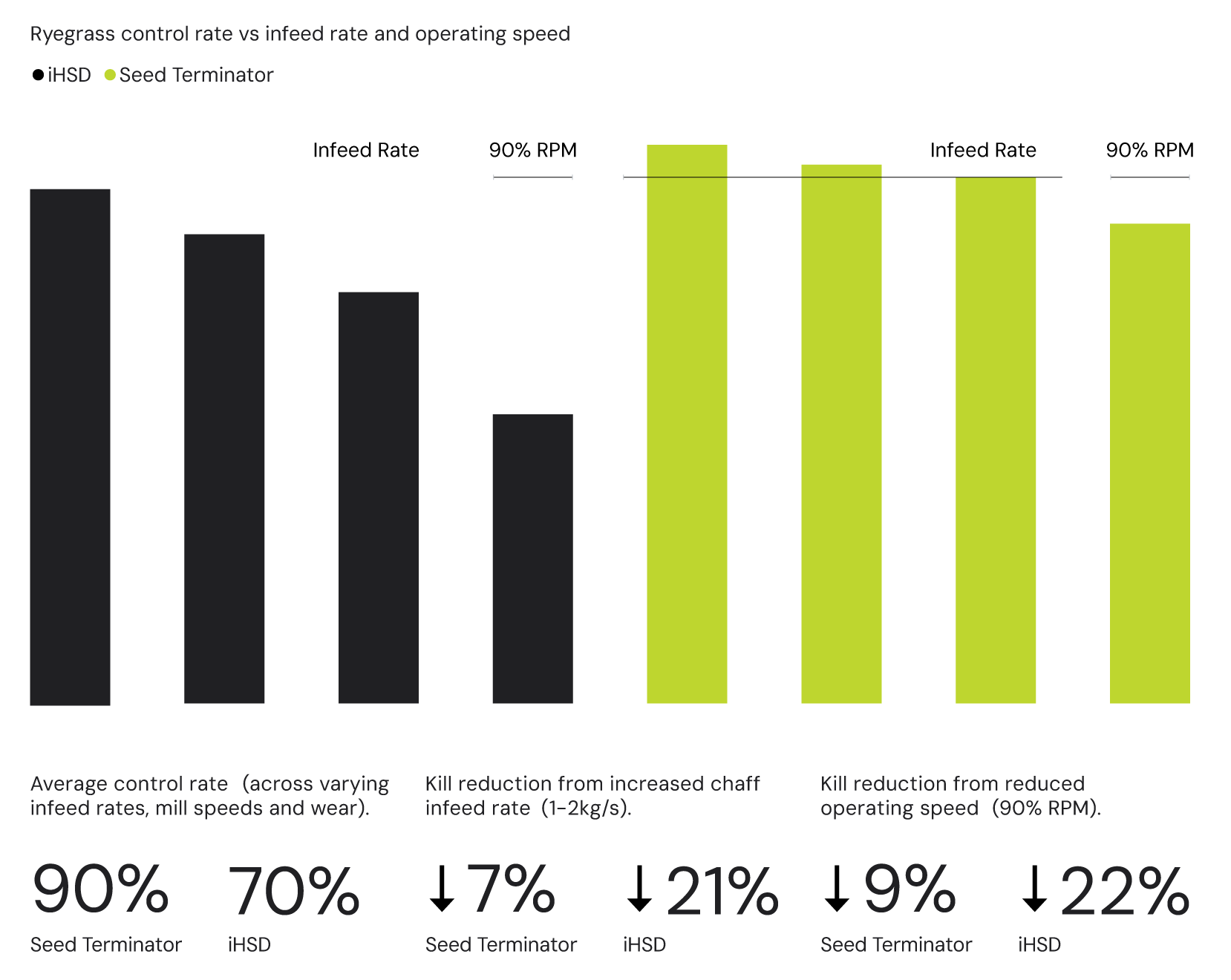

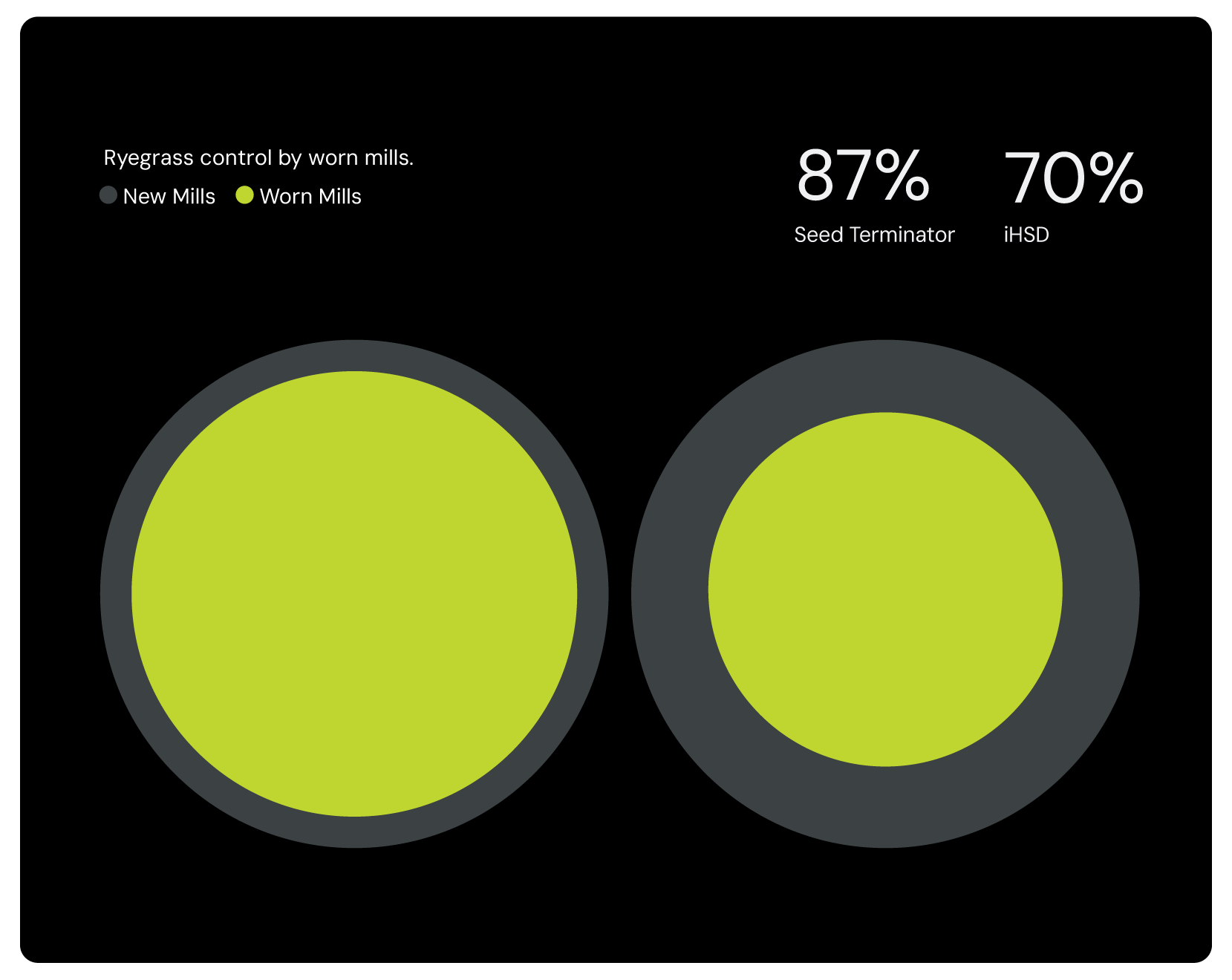

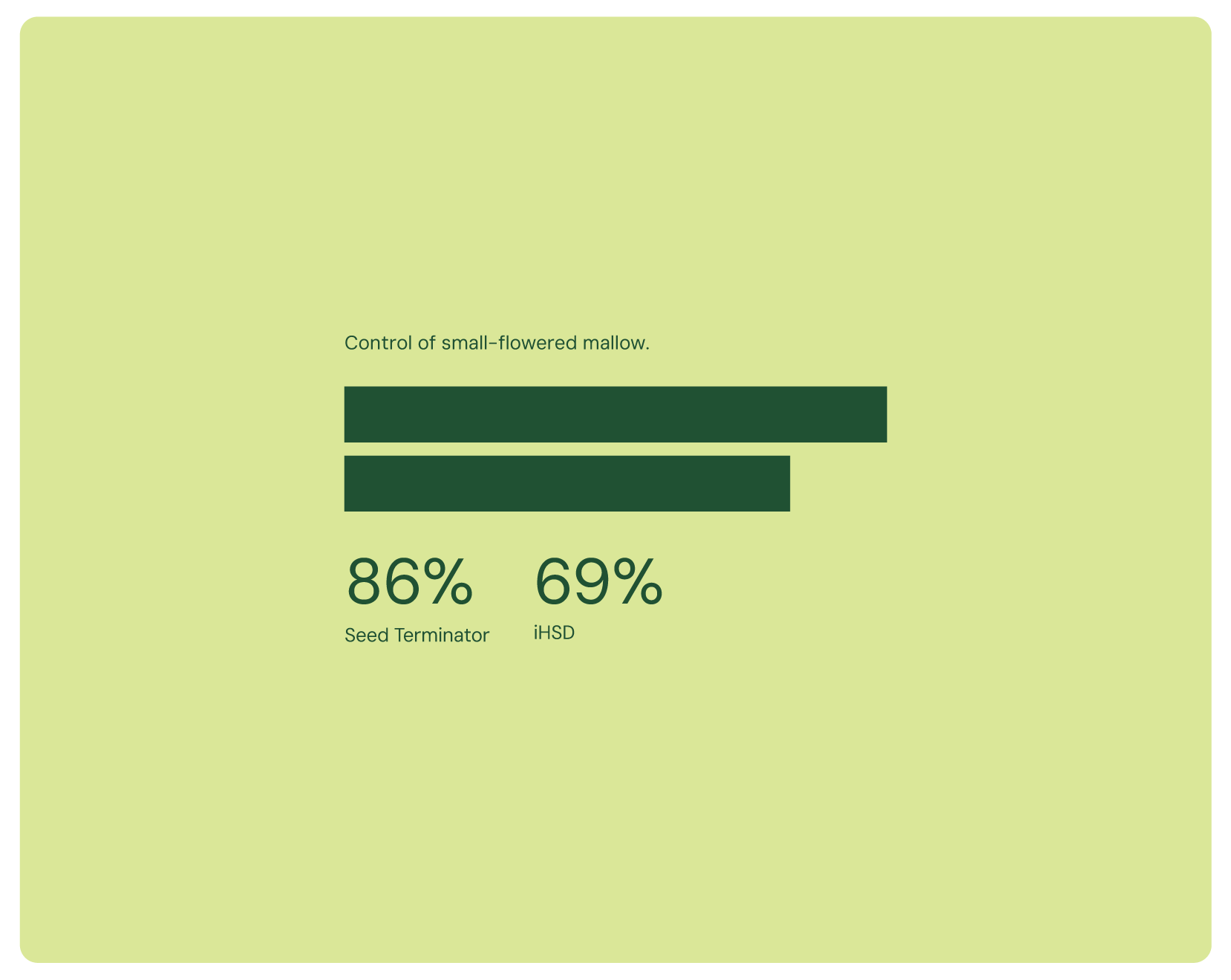

The latest independent research by Sam Trengove funded by SAGIT comparing weed seed kill rates of impact mills, including Seed Terminator iHSD and Redekop. It evaluates performance under varying mill speeds, wear, and chaff flow rates.

University of Missouri Research [USA] 2020

University of Missouri research found that around 80% of waterhemp seed is captured by the combine, and the Seed Terminator destroyed 93.2% of what entered the mill. A practical tool to reduce the weed seed bank at harvest.

Pilot Mill Benchmark Testing 2021

Original pilot test results from 2021 with a limited testing program, benchmarking all three mill manufacturers; Seed Terminator, Redekop & iHSD.

Kondinin Research Report 2020

The war against weeds continues with learnings from 20 farmers across Australia.

Kondinin Research Report 2018

Early learnings around mill technology and harvest weed seed control.

Original 2017 SAGIT Testing

Optimisation of Seed Terminator settings in the South Australian Context from Sam Trengove, Trengove Consulting.

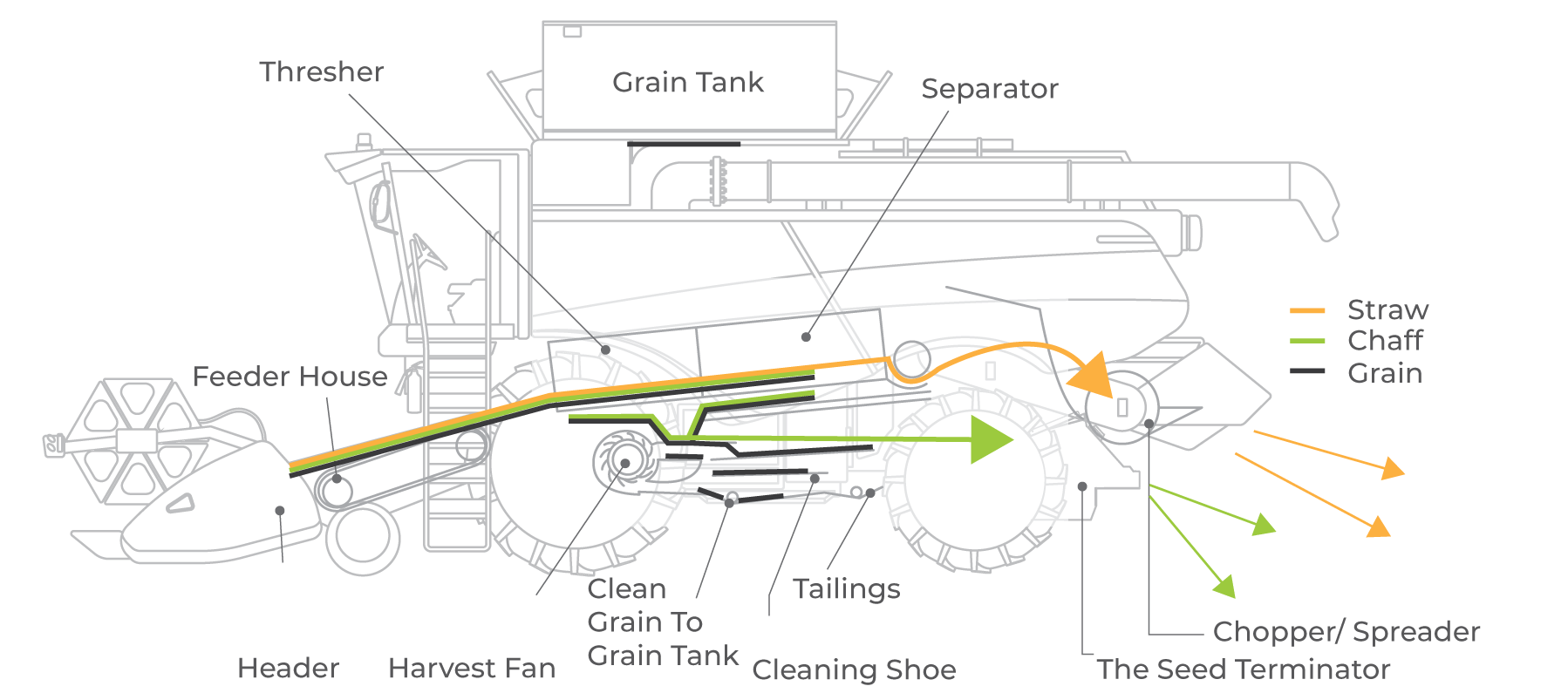

Why do combines spread weeds?

Let's unpack what is going on inside the combine harvester

Material Function

What factors affect the likelihood of a weed seed being terminated?

An overnight success story, a decade and counting.

Insight in how a young farm kid from Kangaroo Island, South Australia became the world expert in stopping 80% of the worlds weeds being spread from the back of combine harvesters. Globally.

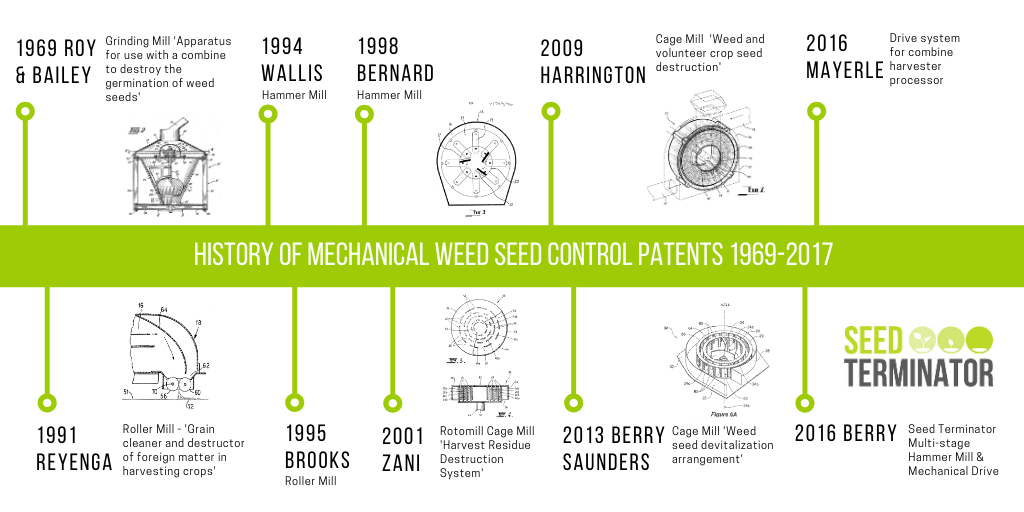

Let’s reel back a bit. Quite a bit, actually, to the 1960s. Back then, the herbicides available weren’t up to much, so farmers had to rely on tillage – churning up the soil prior to planting - to control weeds. They knew it wasn’t ideal.

Then along came a significant change. “All of a sudden we started to get some really effective chemicals come out, like glyphosate, which facilitated a whole change in agricultural practice. We moved away from tillage altogether, particularly in Australia.”

Still the world’s most used herbicide, glyphosate saw yields go up, and a lot of area that wasn’t suitable for cropping suddenly became viable. Globally, glyphosate use has risen almost 15-fold since “Roundup Ready,” genetically engineered glyphosate-tolerant crops were introduced in 1996.

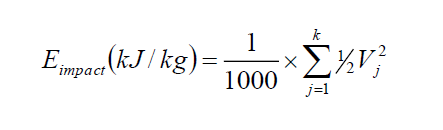

- 2011: Critical Impact Energy for Wimmera Ryegrass Control 'Determination of Critical Impact Energy to Devitalise Wimmera Ryegrass (Lolium Rigidum) Seeds' Nick constructed rotational, drop weight, and pendulum impact testers to determine the criticial impact required to kill Wimmera Ryegrass (Lolium Rigidum), wrote a paper and spent the next decade getting a machine to do it on headers, in paddocks.

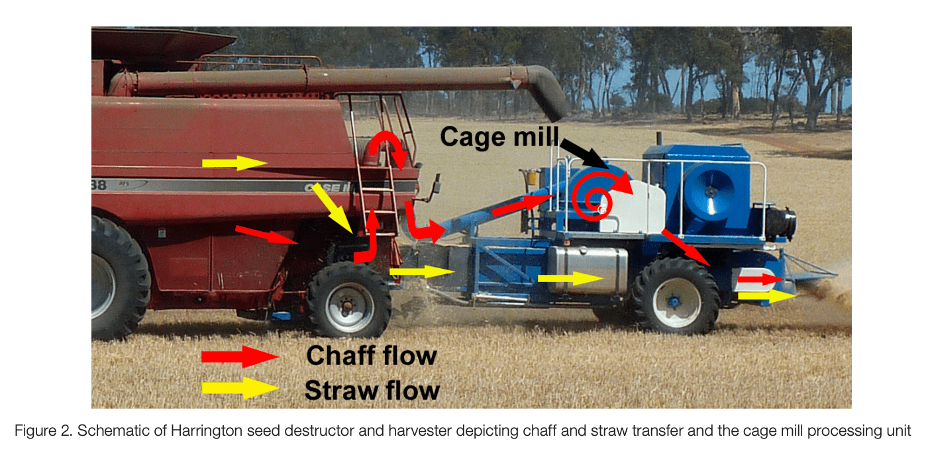

- 2011: Enhancements in Harrington Seed Destructor's Chaff Transfer 'Improving the Chaff Transfer System of the Harrington Seed Destructor (HSD)' This study looked at the role of airflow and evaluated Pneumatic Conveying System over the existing cross augers and slinger fans used by chaff carts at the time to improve the chaff transfer system of the Harrington Seed Destructor.

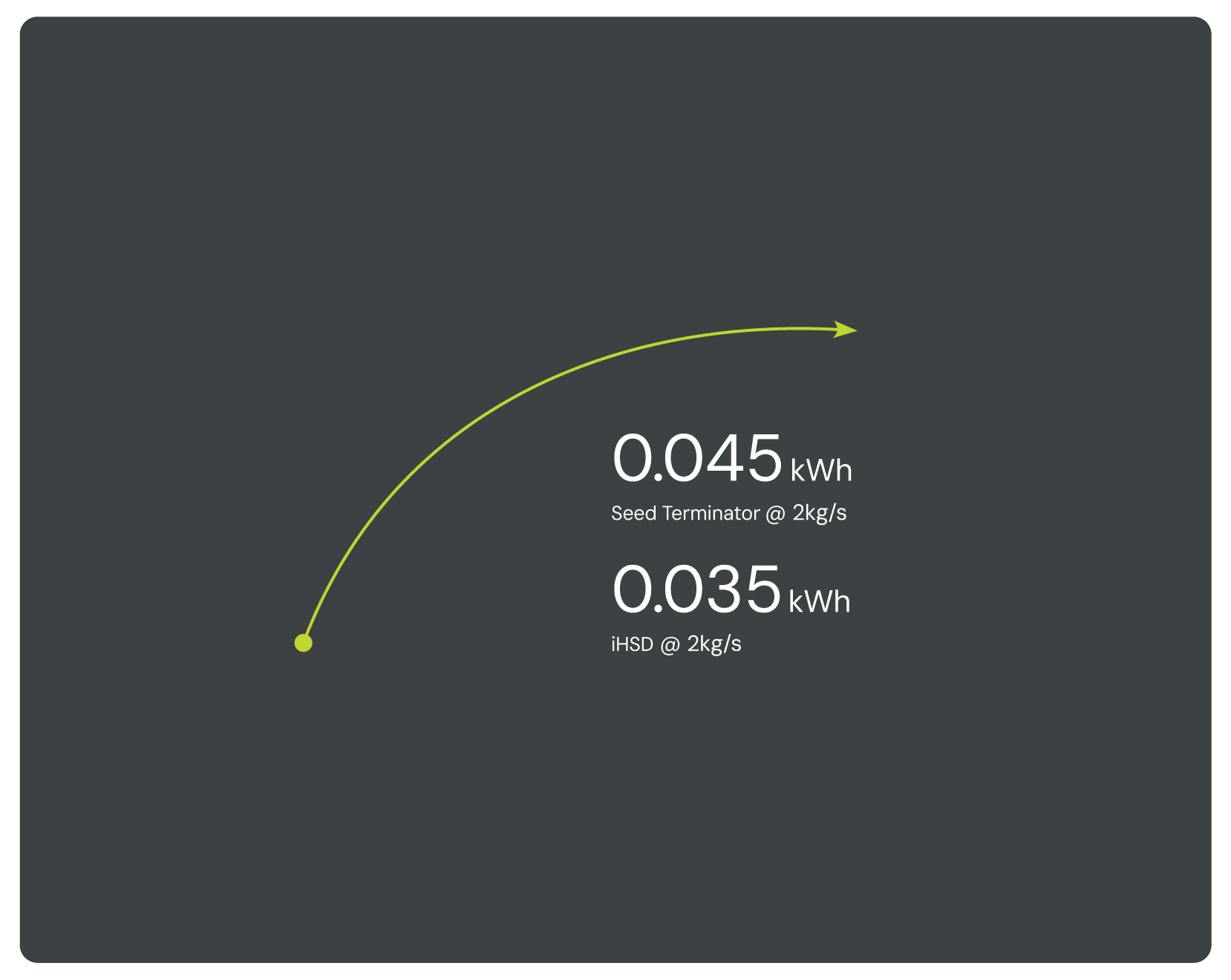

- 2012: Power Use in the Harrington Seed Destructor 'Relating the power used by the Harrington Seed Destructor to chaff throughput' Previously limited to use with Class 6 harvesters, Nick monitored the power required over varied chaff and grain rates to determine the No Load Power & Chaff-to-grain ratios (to scale to other harvesters) with the HSD Version II on a JD 9650.

- 2013: Difference in terminal velocity of wheat chaff particles and Annual Ryegrass (Lolium rigidum) 'Opportunities to reduce the chaff processing requirements of a harvester weed seed destructor' The energy requirements to terminate weed seeds was immense. Nick explored reducing the amount of chaff being processed as an avenue to reduce that requirement. Aerodynamic removal could theoretically eliminate 22% of chaff while retaining 95% of Ryegrass seeds. Sieving alone could collect 90% of Ryegrass seeds, removing up to 30% of chaff.

- Integrated Seed Destructor Patent 'Weed seed devitalization arrangement'

- 2014 PhD Thesis! 'Optimisation of an impact mill that processes chaff exiting a combine harvester to devitalise annual ryegrass (Lolium rigidum) seeds'

- 2015 Mastercurve predicting Ryegrass seed devitalisation 'A Mastercurve to predict annual ryegrass (Lolium rigidum) seed devitalisation when exposed to multiple single sided impacts' The mastercurve has wide implications when using impact to kill ryegrass. This accurately predicts % kill based on number of impacts, speed and seed moisture content.

'A multistage hammer mill and a residue processing system incorporating same'

An advantage of hammer mills is that in addition to impact, they induce crushing, shear and attrition forces that make them particularly useful for size reduction of fibrous materials. Another advantage of hammer mills is that they often have flexible impact elements that are replaceable and can handle some foreign objects without damage

Seed Terminator Pro for John Deere X Series

Seed Terminator Flex for New Holland

Terminator Agro Translates

'A PhD on Smashing Weeds'

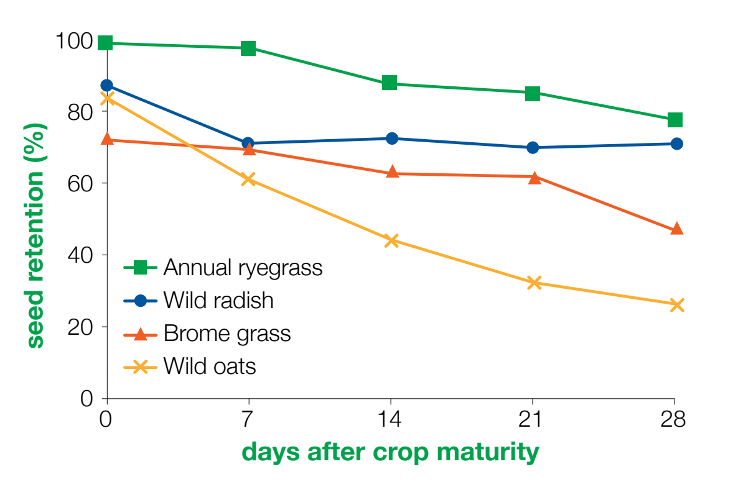

Take a look at Target Weed Species