20MIN

CHANGE OVERS

97%

KILL RATE

DESIGNING A NEW ERA OF POWER.

Forget everything you know about a Terminator.

We did the impossible.

Designed from the ground up to suit the latest combine harvesters, incorporating over a decade of learnings, this is the next generation of Seed Terminator.

Welcome to the fleet X9.

Defining the new standard.

01

Design to kill enemy number one - Annual Ryegrass

02

Ensure minimal impact on the harvester

03

Build the most efficient driveline yet

04

New simple bypass

05

Take the chopper all the way home

06

Maintain access to sieves

07

Handle over 115 tonnes of throughput an hour

08

Broad spectrum weed control

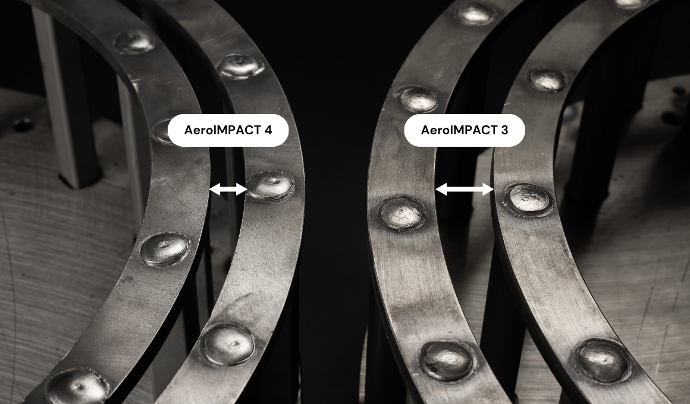

Introducing AeroImpact 4

100% Performance

By tightening the tolerance between screen and rotor we’ve perfected each phase of termination, increasing capacity while maintaining >97% kill.

Long Wearing

We’ve taken the next step to 10mm thick Australian Made bisalloy steel for longer lasting screen tech that goes the distance.

Rotors Reimagined

Capacity is king

Increasing the speed of the mills to 3200RPM allows them to perform with a high volume of throughput. With upwards of 8 B-Doubles of chaff going through an hour in an average wheat crop, we know capacity is king.

100% Performance

By tightening the tolerance between screen and rotor we’ve perfected each phase of termination, increasing capacity while maintaining >97% kill.

External Tensioner

Easy access to adjust the tensioner without pulling anything apart

Horizontal Orientation

Allows for even spread. No gyroscopic forces.

Built for high performance

Utilising the best of existing design like our German Gearbox

Compact with clearance

Designed to be simple, robust and compact, this new platform delivers

Safety & bypass

all the features you need

01 Full ISOBUS integration on CommandCentre™

02 New simple bypass

03 SmartALARM technology as standard

04 Vibration for early wear detection

05 External Gearbox temperature monitoring

06 Left and right mill speed sensors

ISOBUS as standard

Full ISOBUS integration on CommandCentre™ with SmartALARM, vibration, speed and temperature monitoring

2 x Magnet trays

Double magnet tray 162 rare earth magnets each with 9.2kg pulling force to capture metallic objects off of the cleaning shoe

Active feed

Utilising the shaker tray to actively feed the Seed Terminator means no blocks and harvest moves forward

Fits to both John Deere X9 1000 & 1100 combines. Compatible with all residue and tyre options.

Sliding driveline maintains access to sieves.

Take the chopper all the way home.

Lightweight stainless chutes for easy one person removal.

No limitations to premium residue package - swath away.

6 bolts to replace screens ~20 minutes. Rotor and flails add ~60 minutes. Fully balanced from factory for plug and play.

Sixth generation gearbox, as proven over other platforms.

24 month driveline warranty and 12 month warranty covering all components other than wear items.

Want a brochure?

Got an X9? Harvest is your chance to hit ryegrass where it hurts. Download the Seed Terminator Pro X brochure and see how Terminator tech fits your machine.

Josh Lade, Saskatchewan, Canada