EARLY ORDER SAVINGS ON NOW

Origin S for John Deere

Highest savings available on orders by 31.12.25

Early Order Deals close on 31.3.26

01

Efficient by design

Custom designed German manufactured spiral bevel gearbox that runs at a low 1580RPM without the complication of a cooling system.

02

Upgradeable with easy access

Designed to be easy to live with.

03

Future Proof

New mill technology stays compatible with machines. Plus mill options for tough conditions.

04

Quick, Easy Servicing

Easy-access design allows for quick, plug & play change-outs for upgrades, repairs and maintenance. While retaining access to inspect or replace the sieves.

Perfecting the balance of kill rate, power and wear.

The RRP for a Seed Terminator ranges from $115,000 to $125,000 AUD fitted, depending on make and model.

Our Early Order Program is the best time of year to lock in savings on your new Seed Terminator.

Includes: our Proven Mechanical Drive with SmoothFeed 2 updates, Future Proof Chassis, Latest AeroIMPACT Mill tech, Magnet tray, NEW: SmoothFEED 2 Chutes, NEW: Improved Bypass, In cab monitoring system, NEW: SmartALARM, Delivery, Fit-up and Commissioning.

Research emphasises the significant energy required to effectively destroy small seeds, highlighting the necessity of power for successful seed termination.

- High Energy Demand: Essential for targeting tiny Annual Ryegrass seeds.

- Power Equates to Efficiency: A direct correlation with seed termination.

- Estimated Power Requirement: Approximately 80-100 horsepower needed.

Yes, we aim for this to be a future proof technology platform, able to slot in the latest mill technology available in two or five years' time.

John Deere s-series | s670, s680, s690, s770, s780, s790 + Premium Residue Package

For X-Series click here

The inside story

Join Dr Nick Berry as he walks you through the updated MY23 platform.

Explore the new SmoothFeed 2, updated bypass, SmartAlarm, single belt design and chopper home in the position.

Learn the intent behind the engineering design, and see the new platform in detail.

It’s a beast.

Specifications

*All S670 & S770 models will require for the main drive pulley on the main engine gearcase to be replaced with CE20125.

Yes the Seed Terminator is CTF compatible and can run on 3m centres with most tyre packages.

The Seed Terminator includes

- Proven Mechanical Drive

- Chassis

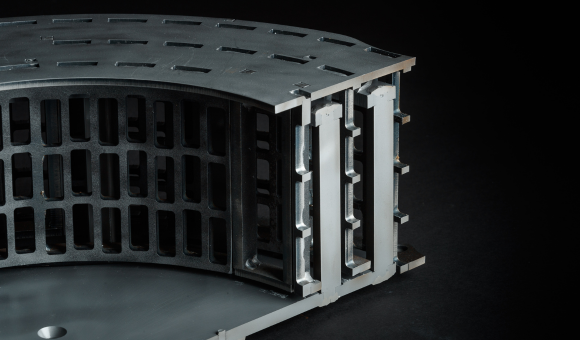

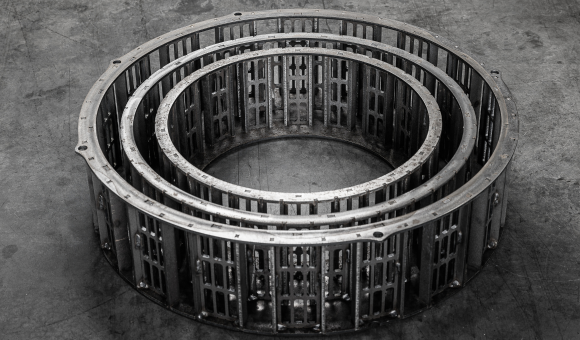

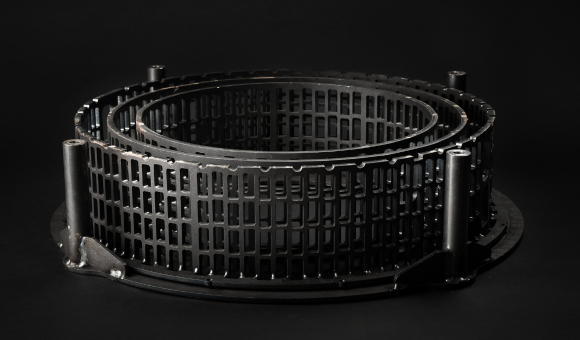

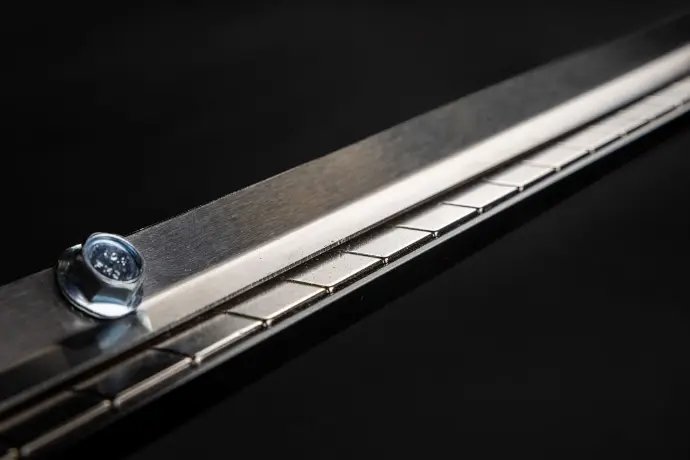

- Latest AeroIMPACT mill tech

- Magnet tray

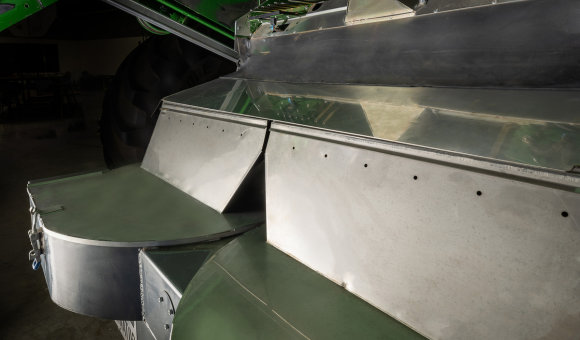

- NEW: SmoothFEED 2 Chutes

- NEW: Improved Bypass

- In cab monitoring system

- NEW: SmartALARM

Installation can be completed in a day with two technicians.

All machines will require 4 holes to be drilled through the rear hitch plate for mounting of the Seed Terminator, magnetic drill templates can be purchased to mount the drill for ease of locating. We recommend and use a Mag Drill to penetrate the 18mm hitch.

*All S670 & S770 models will require for the main drive pulley on the main engine gearcase to be replaced with CE20125.

Combine Harvester will require 4 holes to be drilled through the rear hitch plate for mounting of the Seed Terminator, magnetic drill templates can be purchased to mount the drill for ease of locating.

All S670 & S770 models will require for the main drive pulley on the main engine gearcase to be replaced with CE20125.

All equipped with the intermediate residue package (100 knife chopper) the main drive pulley (HXE12052) on the chopper jackshaft with HXE117754 and drive belt (H240974) with (HXE124869).

The Seed Terminator for John Deere S-series comes with our 2 year driveline warranty and a 12 month warranty period covering all components other than wear items so there's nothing holding you back. From the Original Equipment Manufacturer (OEM) the Seed Terminator is looked at as an attachment and the warranty will not be affected by the installation of the Seed Terminator.

Want a copy of the brochure?

Josh Lade, Saskatchewan, Canada

Sign up below and we will shoot you a copy via email.