EARLY ORDER SAVINGS ON NOW

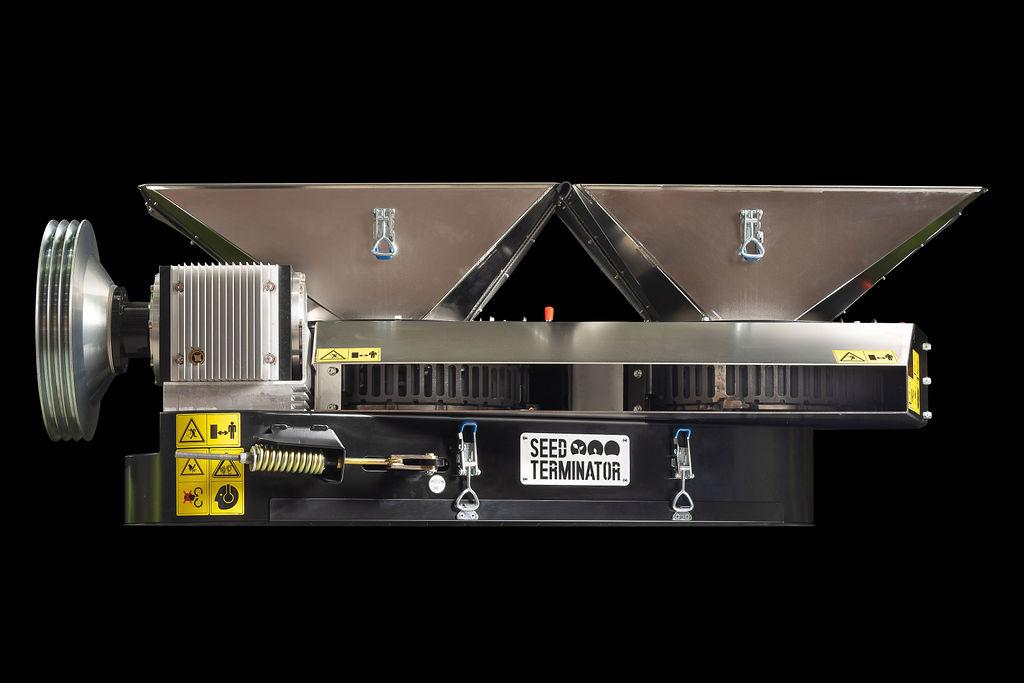

Pro 1000 for CLAAS

Highest savings available on orders by 31.12.25

Early Order Deals close on 31.3.26

Register for a quote here

01

Designed to kill enemy #1 - Annual Ryegrass

The latest in performance and efficiency built on the science of mechanically killing weeds.

02

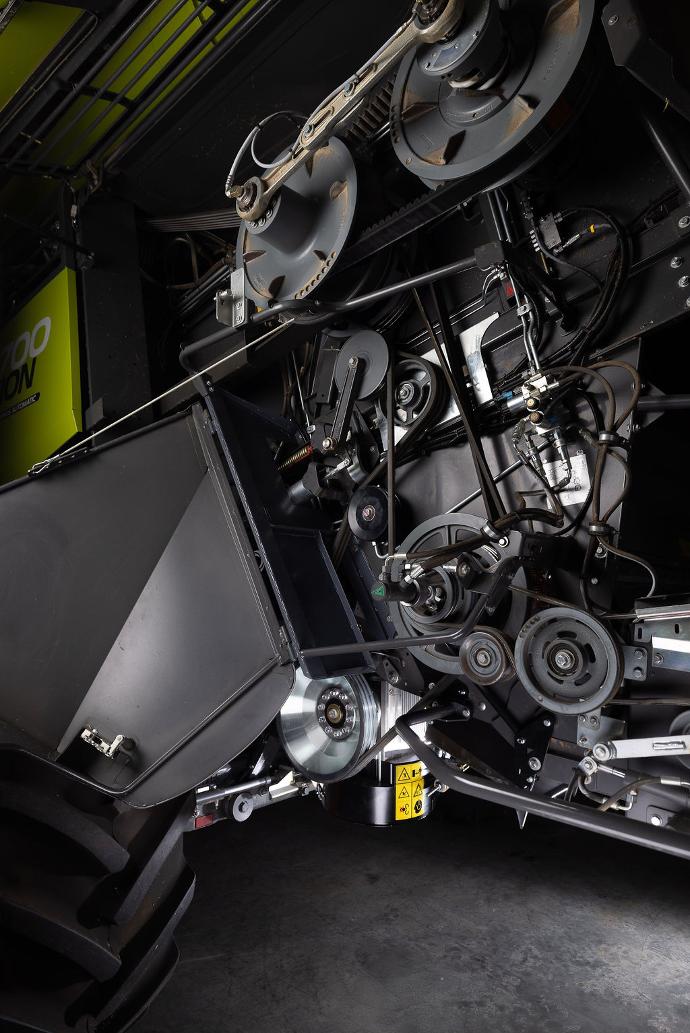

Compact with exceptional clearance

Designed to be simple, robust and compact, this new platform delivers.

03

Low impact install plus install time is halved

Compared to Seed Terminator Origin.

04

Simple manual bypass

We’ve included bypass for the first time on this platform. Simply remove the chutes and baffle, install the specialised bypass tray and drop the belt. Material will be put into windrows perfect for grainloss testing.

05

Active feed for improved chaff flow

Utilising the shaker tray to actively feed the Seed Terminator means no blocks and harvest moves forward.

06

Side drive optimised

Inertia is shared between the chopper and Terminator driven pulleys, increasing overall tension and directing drive to where the greater load is required.

07

Latest F1 Monitoring system

With vibration for early wear detection, SmartALARM technology (Excl MAN engine), external gearbox temperature and left and right mill speed sensors.

08

Quick, Easy Servicing

Easy-access design allows for quick, plug & play change-outs for upgrades, repairs and maintenance. Plus a auto grease line has been added.

INTRODUCING AEROIMPACT 4

100% PERFORMANCE

By tightening the tolerance between screen and rotor we’ve perfected each phase of termination, increasing capacity while maintaining >97% kill.

LONG WEARING

We’ve taken the next step to 10mm thick Australian Made Bisalloy steel for longer lasting screen tech that goes the distance.

10 MINUTE SCREEN CHANGEOUT

Our latest screen design is even faster to change out with 10 minutes. You’re welcome.

AEROIMPACT 4 VS AEROIMPACT 3

CAPACITY IS KING

Increasing the speed of the mills to 3200RPM allows them to perform with a high volume of throughput. With upwards of 8 B-Doubles of chaff going through an hour in an average wheat crop, we know capacity is king.

100% PERFORMANCE

By tightening the tolerance between screen and rotor we’ve perfected each phase of termination, increasing capacity while maintaining kill

The Beast overview

Dr Nick Berry runs through the full Pro 1000 setup for CLAAS Lexion in this 8-minute video. From mill tech to belt drives and chaff distribution, it’s everything you need to know.

Side drive

optimised.

Inertia is shared between the chopper and Terminator driven pulleys, increasing overall tension and directing drive to where the greater load is required.

Less belts, more drive.

A single 3-groove serpentine belt drives both mills with strength for the toughest of conditions. High end EPDM belt technology delivers superior performance, while protecting the harvester.

The Pro 1000 has been designed for optimal pulley geometry underneath. This configuration ensures efficient belt wrapping for max performance.

Engineering for a world that never goes hungry.

Discover the future of sustainable farming with the new Seed Terminator Pro 1000.

Limited Release for Australian Harvest 2024, now available for CLAAS 1000 series machines.

She's a beast.

THE NON-CHEMICAL SOLUTION

Compatible with Comfort Plus and Premium Plus choppers.

MAN D42, Mercedes OM 473 La and Perkins 2206 D engines are compatible.

Note Modifications: OEM Tensioner and Slow Chopper Speed Drive removed

- The low-speed chopper drive will be removed; therefore, with the original clutch, only high speed and neutral are usable.

- Optional Ad On: The Chopper Clutch Delete Kit is an added cost option, giving one set speed.

- Optional Ad On: Medium Speed Kit aims to aid chopper throughput in very dry cereal crops.

NOTE: Windrowing/swathing is not achievable with the Clutch Delete and Medium Speed Kit.

Simple side drive, with simple install for minimal impact on the harvester.

Compact system with exceptional clearance.

Lightweight stainless chutes for easy one person removal.

5 bolts to replace screens ~10 minutes. Rotor and flails add ~60 minutes. Fully balanced from factory for plug and play.

Sixth generation gearbox, sped up for less torque.

Running our proven gearbox at higher speeds reduces the torque on drive components for improved efficiency. It’s cooled by three heat sinks and airflow from the outlet. Mounted on an aluminium block for added heat dissipation.

24 month driveline warranty and 12 month warranty covering all components other than wear items.

- Latest release F1 Monitoring System.

- New simple bypass.

- Vibration alarm for early wear detection.

- External Gearbox temperature monitoring.

- Left and right mill speed sensors.

- Magnet tray as standard.

Want the

Pro 1000 brochure?

Built to match the horsepower and capacity of CLAAS Lexion combines, it’s the next level in integrated weed control. Download the product overview brochure and see why it’s built for the big leagues.