MY18 Multi-stage Hammer Mill

- 96% Kill Performance

- The Multistage Hammer Mill uses a combination of shear, crush, attrition and high impact to kill weed seeds.

- It has three stages of screens to classify material for size.

- The chaff material and weed seeds must be smashed small enough to fit through each stage of screens. The process uses large openings which progressively get smaller.

- Multiple stages enable high capacity while maintaining pulverisation to consistent level at a range of rotational speeds.

The Multi-stage Hammer Mill is made from heavy duty, high grade case hardened steel, using CNC precision machining. CNC precision machining is also harnessed to make robust flame hardened central replaceable flail hammers. It can be operated at dual speeds of 2750 and 2950 RPM and features adjustable pulverisation Bisalloy screens with Advanced Surface Engineering Tungsten Carbide Shield to fight the war on wear.

Mechanical Drive - 31% Less Power

We designed a mill that can handle drops in engine RPM without significantly effecting capacity or kill, which enabled us to harness the efficiency and simplicity of the mechanical drive without being tethered by fluctuations in engine rpm. Our drive is driven off the harvester’s engine with minimal moving parts, incorporating only shafts, belts and gearboxes. This is to maintain a lower power draw and fit to class 7-10 harvesters. We use precision machined custom bearing spindles and a custom, German made spiral bevel gearbox.

The War on Wear

We have attacked wear on multiple angles this year with

- Aero-IMPACT 2.0 improved aerodynamics with 31% less power

- We have optimised the residence time that material is in the mill to reduce wear and over processing

- We have created Advanced Surface Engineering Techniques to apply a Tungsten Carbide coating to our mills and rotors

- As well as Optimising Particle Flow in the mill to identify and remove the weakest links

Aero-IMPACT 2.0

We created the Aero-IMPACT 2.0 system that efficiently creates high air flow for maximum capture of weed seeds, minimum disruption of the harvester sieve and minimise infeed blockages. Uniquely able to maintain high air flow under highly loaded conditions even at reduced rpm. We have optimised the residence time that material is in the mill, to improve capacity, reduce wear and reduce over processing. We have also improved the aerodynamics of our impact elements which has meant less turbulence and therefore less wasted energy.

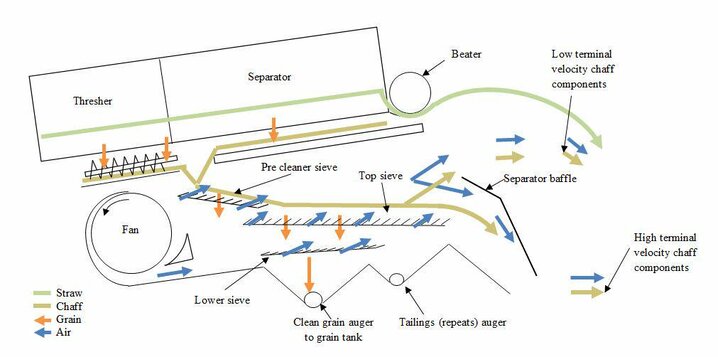

The diagram above shows the movement of straw, chaff, grain and air in the harvester. The baffle-beater gap let's air escape unrestricted, too much air escaping above baffle = risk losing seeds. Seed Terminator's huge air flow means less air escaping above baffle = no cleaning shoe air restriction and maximum capture of weed seeds.

As you can see in the video material is sucked into Multi-Stage Hammer Mill even with the side covers off.